Wine-making machines

Prodotti

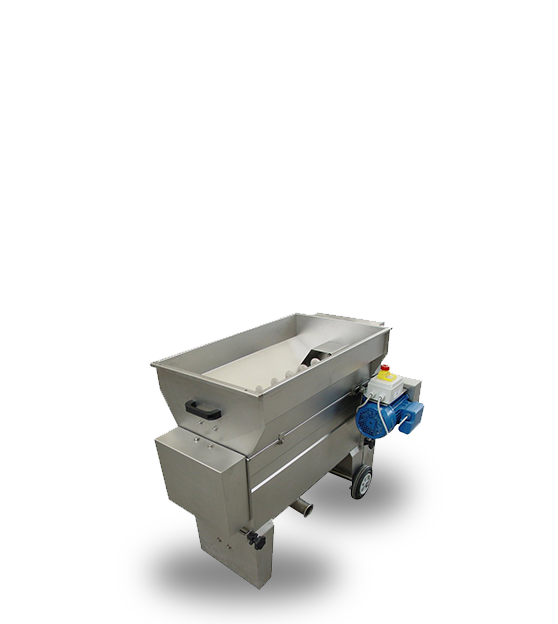

ROLLTEC is a selection table with rollers conceived for the separation of the grape berries from all waste parts, such as leaf stems, leaves, stems, small not ripe or dry grapes, and other foreign bodies. ROLLTEC is equipped with a vibrating hopper in the machine inlet that spreads the product evenly on the separation rollers. The series of rollers is subdivided in two parts; on the first section there are six rotating shafts with rollers, having a profile specially conceived to eliminate small not ripe grapes, dry grapes,.residues, etc; on the second section there are nineteen rotating shafts with rollers, having a profile suitable to let the whole grapes drop below, retaining above the stems and the leaf stems until they are eliminated to the discharge conveyor. The spacing between rollers is easily adjustable in a continuous manner through special handles placed outside the machine. The adjustment of the first series of rollers is independent from the second, so the work can ideally adapted either for the separation of the grape waste or for the whole grape screen.

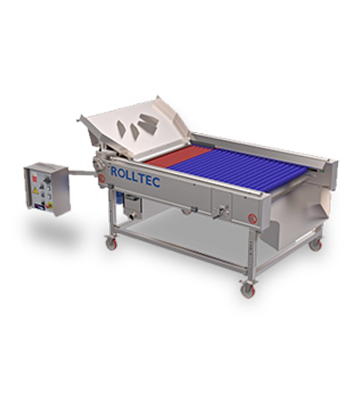

Machine destined for the manual selection of hand-picked or machine-picked whole grapes, or stemmed grapes, in order to remove all waste components, such as damaged grapes and bunches, bunches not ripe, leaves and other foreign bodies. The advance of the grape is obtained from the vibration of the work surface created through the combined action of dedicated moto-vibrators. On its initial part the work surface has an under grille for the immediate recovery of the excess of liquids (must flowers) with the use of a basin placed below equipped with a garolla fitting or others under request. Appropriate side rails placed along the total length of the table, which can be quickly mounted, make easier the separation and advance of the waste product, from that destined to subsequent processing. Electrical panel with electronic variable speed drive (inverter), allowing the quick variation of the product advance speed.

The elevator belts are used to transport with maximum care grape in bunch, stemmed or fermented residues. The elevator belts of the series M250 - M400 have trolley and 4 wheels of which 2 pivoting to make displacements easier. They can be supplied in several lengths, according to the requirements, and as standard with a series of hydraulic pistons commanded by the manual pump for the height adjustment. The conveyor belt is in PVC suitable for contact with food, with concave profile slats with H=50 mm. The belt structure has double channels to render very simple the cleaning between the upper band and the lower band. The conveyor is also equipped with a scraper and collection basin. Can be supplied with variable speed drive upon request.

TS800 is used to manually remove all harmful components and, therefore, even spoilt grapes, unripe bunches, leaves and other foreign bodies. They can be supplied in various lengths and can be adjusted to 5 different heights, according to need. The conveyor belt is in PVC suitable for contact with food. Special attention has been afforded to facilitating machine cleaning: the rear manhole opens, allowing quick cleaning of the lower channel of the table; the upper surface supporting the belt is perforated to allow the rinsing water to drain, thus preventing stagnation under the belt. The liquid flowing out of these holes is recovered by two dedicated basins. The TS800 is also equipped with scraper with collection basin. The selection is carried out by the special separation channels: the grapes and bunches advance to the centre, while all the damaged or foreign parts are pushed to both sides.

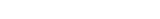

Positioned before the selection table, the TVD1 allows the dosing and distribution of the grape in an uniform way favouring the sorting of the product. The advance of the grape is obtained thanks to the vibration of the horizontal surface, which being perforated on half of its length, allows the recovery of the excess of must and a first cleaning of the grape. The TVD1 can also be used before the stemming machine to feed the grape in a constant and uniform way. It is possible to equip the TVD1 with an electronic variable speed drive (inverter) for instant variation of the product advancement speed.

DREAM is the new stemming machine conceived for the delicate processing of grapes. The machine is built with high-thickness stainless steel plates and large dimension profiles that ensure a solid and robust structure. The stemming of the grapes is obtained thanks to the wave-like movement of a cage in plastic material specially perforated. This way, a delicate action is obtained allowing the separation of the grape from the stem leaving the grapes whole, even in the case of grapes difficult to stem.

New generation stemming-crusher, designed to achieve the best qualitative results, at the same time supported by an extreme adaptability to the product, which reduces to a minimum the quantity of MOG and makes the disassembly and cleaning operations much easier. DINAMICA stemming machines stand out for the modularity of their unloading height (with telescopic legs and/or telescopic frames) for use in manual and automatic sorting lines, standard equipment including beaters with height- and tilt-adjustable full-rubber blades, enhanced-thickness PVC cages (10mm) with round 24, 22, 19 mm or progressive holes, for Dinamica 60 and Dinamica 100. The models Dinamica 150/250 offer as standard beater and cage in stainless steel (beaters with rubber blades and cages in pvc upon request). All models are equipped with an electronic variable speed drive for the stemming part, the crushing unit in food-grade rubber with independent drive and with the distance adjustable from outside.

The machine feed is regulated by an auger located in the receiving hopper. The grapes are then taken up by the stemming shaft that rotates inside the perforated cage (grid) with holes suited to the different grape varieties and harvesting methods. The sheet metal of the grid has round, flared holes to avoid tearing the stalks. The processing speed is variable and adjustments can be made to obtain whole grapes. The grapes then fall onto the fine-toothed rubber rollers, which ensure proper crushing and can be adjusted using two handwheels on the outer side of the machine.

The stemming machine F50 is totally built in stainless steel AISI 304 and equipped with a large loading hopper with screw feeder, rotating drum and the stemming unit with rubber rollers. A mechanical coupling allows the quick disconnection of the stemming unit (RG), should the stemming phase be omitted. The stemming shaft has a speed of 500 rpm at the 1st speed and 650 rpm at the 2nd speed. The machine speed can be changed through the transmission belt.